Review: Setra Room Pressure Monitor

This post will review the Setra Room Pressure Monitor and show a full feature review as compared to other room pressure monitors.

The Setra SRPM is commonly used in cleanrooms, positive pressure rooms, negative pressure rooms, negative pressure isolation rooms, and in sterile compounding rooms. The Setra SRPM can also monitor temperature (within limited ranges) and relative humidity (RH).

The Setra Room Pressure Monitor Model SRPM is a re-branded product that several other companies have chosen to feature. The Setra SRPM is identical in features and Chinese-based manufacturing you will find in other brands and products such as the:

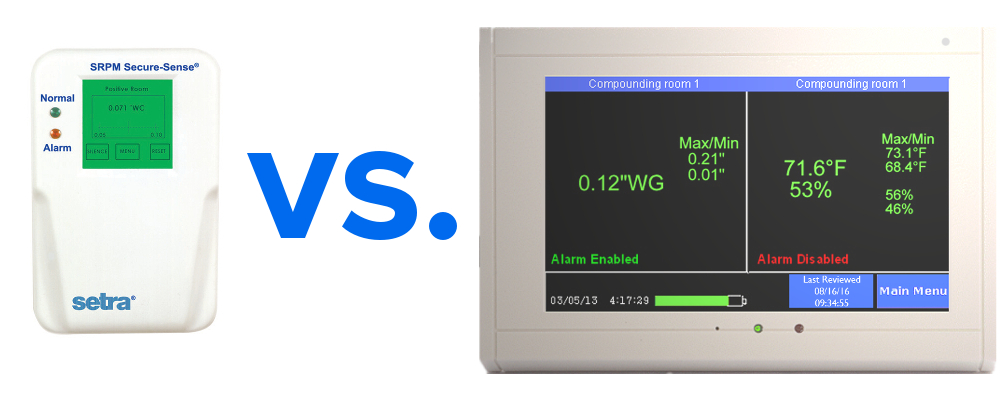

In this product review, we will compare the Setra to the TV2 Room pressure Monitor in a feature-by-feature comparison table below.

[easy-pricing-table id=”1491″]

The complete line of Setra Room Monitoring instruments is popular and well-known throughout the industry. however, there are other comparative options that offer more robust functionality and data logging options. The TV2 Room Pressure Monitor is a great alternative to the Setra Model SRPM.

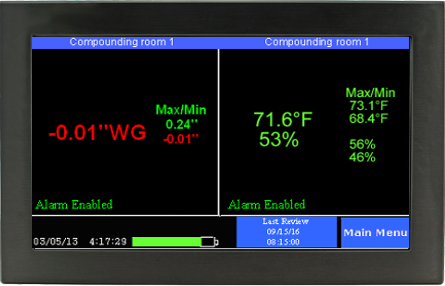

Both the Setra SRPM and the TV2 Room pressure Monitor are typically used in new construction and post construction applications where differential pressure are monitored. Althought the Setra has a monochrome touchscreen, the TV2 Room pressure Monitor has a full-color QuickCheck easy-to-read large touchscreen with an intuitive menu system.

One of the key features of the TV2 as compared to the Setra is the ability of the TV2 Room pressure Monitor to alert admins by SMS (text alert), by email, and by automated phone alerts with custom messages.

Additionally, the TV2 automatically logs all data and offers complete reporting for environmental conditions, as well as provides remote (LAN/USB) connectivity for monitoring and reporting.

Most consumers would choose the TV2 Room Pressure Monitor due to the wider availability of features and USA-based manufacturing and support.