A data logger is basically a digital recording device that stores data at specific intervals. This logged data can be many things, but in most cases a data logger collects temperature and humidity information from a specifically defined environment.

Data loggers typically consist of a master control unit (to set data collection intervals, set threshold boundaries and to export collected data) and an array of sensors which actually sample the environment and report information.

If temperature and relative humidity (RH) are collected by a data logger, then there must be a temperature sensor calibrated to sense and report temperatures being monitored and a humidity sensor that can detect the amount of water in the environment.

Data loggers are used in almost all industries in the industrialized world. From ensuring food safety to maintaining sterile conditions in medical facilities, data loggers are an integral part of day-to-day life. Probably one of the most widely utilized features of commercial data loggers available is the ability to collect and store data 24 hours a day, 7 days a week. This gives anyone interested, an exportable data set to determine what environmental conditions existed at any point in time.

It is common for data loggers to provide data that may save lives or prevent catastrophe. For instance, a data logger may be used in a pharmaceutical application or medical office where a temperature sensor is monitoring a medical refrigerator housing expensive vaccines. If at some point the temperature drops in the vaccine fridge while no one is actively monitoring it, the vaccines could become ineffective and no one would ever know…until it was too late. Likewise with a great number of medicines and organic/biological applications. Another example might be a data logger in commercial construction. In order for concrete to maintain structural integrity, it must cure at a very specific temperature and humidity level. Imagine concrete used for a bridge or high-rise building; without the ability to review temperature/humidity history from pour to cure. A disaster waiting to happen since any compromise in the curing process could end in disaster. This is why it is important to have a dependable and accurate data logger involved in any process where human life is concerned.

Data Logger Types

Wireless Data Logger: A wireless data logger allows for greater flexibility and post-construction applications. In a wireless data logger, the sensors transmit data samples wireless to a central control device. No wires means system installers can position the sensors almost anywhere a signal can reach.

Thermocouple Data Logger: A thermocouple data logger is a type of data logger that collects temperature information with thermocouple sensors. Thermocouples are classified by various types. The type classification denotes the temperature range it can monitor and its accuracy. Below are the same types of thermocouples and their related temperature ranges of operation.

Type K Thermocouple (Nickel-Chromium / Nickel-Alumel): The type K is the most common type of thermocouple. Inexpensive, accurate, and reliable, with a wide temperature range.

Temperature Range:

- Thermocouple sensor, –454°F to 2,300°F (–270°C to 1260°C)

Accuracy:

- +/- 2.2°C or +/- 0.75%

- Special limits K-type thermocouple: +/- 1.1°C or 0.4%

Type J Thermocouple (Iron/Constantan): The type J is also very common. Lower temperature range and a shorter lifespan at higher temperatures than the Type K but with much better accuracy.

Temperature Range:

- Thermocouple range, -346°F to 1,400°F (-210°C to 760°C)

Accuracy:

- Standard: +/- 2.2°C or 0.75% above 0°C

- Special: +/- 1.1°C

Type T Thermocouple (Copper/Constantan): The Type T is a very stable very accurate thermocouple that can be used for extremely low temperature applications such as cryogenics or ultra low freezers.

Temperature Range:

- Thermocouple range-454°F to 700°F (-270°C to 370°C)

Accuracy:

- Standard: +/- 1.0°C or +/- .75%

- Special: +/- 0.5°C or 0.4%

Type E Thermocouple (Nickel-Chromium/Constantan): The Type E has a stronger signal & higher accuracy than the Type K or Type J at moderate temperature ranges of 1,000°F and lower.

Temperature Range:

- Thermocouple range, -454°F to 1600°F (-270°C to 870°C)

Accuracy:

- Standard: +/- 1.7°C or +/- 0.5%

- Special: +/- 1.0°C or 0.4%

Type N Thermocouple (Nicrosil / Nisil): The Type N shares the same accuracy and temperature limits as the Type K. The type N is slightly more expensive.

Temperature Range:

- Thermocouple sensor, -454°F to 2300°F (-270°C to 392°C)

Accuracy:

- Standard: +/- 2.2°C or +/- .75%

- Special: +/- 1.1°C or 0.4%

Type S Thermocouple (Platinum Rhodium – 10% / Platinum): The Type S is used in very high temperature applications. It is commonly found in the BioTech and Pharmaceutical industries. It is sometimes used in lower temperature applications because of its high accuracy and stability.

Temperature Range:

- Thermocouple grade wire, -58°F to 2700°F (-50°C to 1480°C)

Accuracy:

- Standard: +/- 1.5°C or +/- .25%

- Special: +/- 0.6°C or 0.1%

Type R Thermocouple (Platinum Rhodium -13% / Platinum): The Type R is used in very high temperature applications. It has a higher percentage of Rhodium than the Type S, which makes it more expensive. The Type R is very similar to the Type S in terms of performance. It is sometimes used in lower temperature applications because of its high accuracy and stability.

Temperature Range:

- Thermocouple grade wire, 32°F to 2642°F (0°C to 1450°C)

Accuracy:

- Standard: +/- 1.5°C or +/- .25%

- Special: +/- 0.6°C or 0.1%

Type B Thermocouple (Platinum Rhodium – 30% / Platinum Rhodium – 6%): The Type B thermocouple is used in extremely high temperature applications. It has the highest temperature limit of all of the thermocouples listed above. It maintains a high level of accuracy and stability at very high temperatures.

Temperature Range:

- Thermocouple grade wire, 32°F to 3100°F (0°C to 1700°C)

Accuracy:

- Standard: +/- 0.5%

- Special: +/- 0.25

Alarms: No data logger is complete without some form of advanced warning when a temperature or humidity error is detected. For instance, if a data logger is used to monitor vaccines or expensive medications, there should be data logger software in place to understand the error and send a notification to management personnel.

Ideally, the alarm would be multi-phase; whereas an event is triggered when a temperature range or humidity level falls outside a threshold, and a human is notified by email, phone and text alert. Additionally, it would be advantageous to have a room or loud local alarm to indicate an unsafe temperature or humidity level.

Data Storage: It would be beneficial for a data logger to have the capacity to store up to 80,000 data points over the course of a year or more. This would allow for a complete monitoring solution as well as secure backup. Having the ability to encrypt the data and export it over a secure LAN connection would ensure that it meets 21 CFR 11 standards and that users to have full control over all collected data.

Battery: Any data logger worth having must, operate if power is missing. A good battery backup is essential. It is common for power to fail; your data logger should not. A battery backup should be at a minimum of 72 hours; or, the length of time accumulated over a weekend. This would allow for continuity in monitoring and data collection in the event of a power failure. A data logger should always have a battery backup system – internal or external.

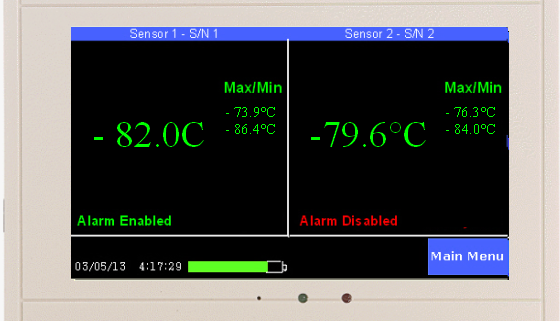

Very few data loggers available offer such a wide range of stability and versatility while maintaining high level of accuracy and dependability. The TV2 Temperature Monitor and Data Logger combines all features and capabilities important to monitoring temperature and relative humidity without compromise.

Learn more about this data logger