Using a Permanent Room Pressure Monitor in a Negative Pressure Isolation Room

Negative pressure isolation room.

Permanent Room Pressure Monitor

Before a new isolation room is occupied, and after the mechanical contractor has adjusted the airflow quantities as directed by the engineer to ensure that it operates as designed it should not be assumed that it will operate under the same conditions for every more. Mechanical systems do drift out of balance over time so it is important to regularly check that an isolation room is still operating under negative pressure; planning for this should be included in the initial design of the mechanical room.

The most reliable way to monitor negative pressure is to install a permanent electronic room pressure monitor as part of the construction project. When properly selected and installed, a room pressure monitor can provide continuous confirmation of negative pressure across a room boundary. This is in contrast to routine periodic smoke testing, which merely provides an indication of directional airflow at the moment of testing. Continuous monitoring can provide instant notification if the pressurization fails or fluctuates during the day.

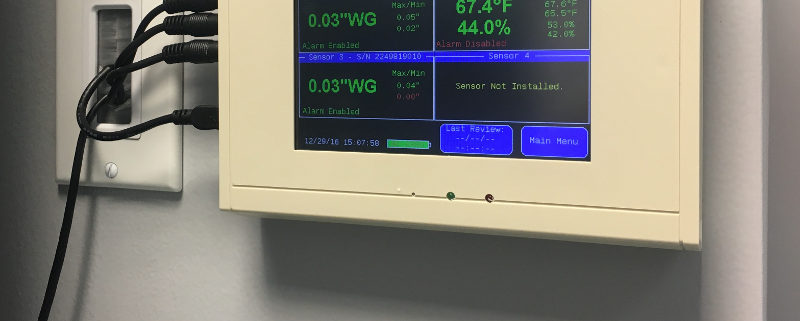

A well-constructed pressure room monitor consist of two main components: a wall-mounted panel and one or more sensors. The panel is usually mounted on the corridor wall just outside the isolation room suite and displays the pressure difference in units of ” W.C.

The best type of permanent pressure monitors are those which measure and display the actual air pressure difference between the isolation room and the reference space. A power supply will be required for the panel.

Pressure differentials across room boundaries can be very small, often in the range of thousandths of an inch. For example, the CDC Guidelines recommend that negative pressure be at least minus 0.001″ W.C. Some devices that measure differential pressure are not accurate to this level. Before specifying or purchasing a room pressure monitor, make sure that the device is capable of accurately and reliably measuring a pressure difference this small.

Direct Room Pressure Monitor

To record a differential pressure, two readings are required: the air pressure in the room and the reference pressure in the corridor. A remote sensor to measure the room pressure is installed in the negative pressure room wall or ceiling with a static port opening in the area being compared. Another sensor measures the air pressure in the corridor. The difference in these two pressure values is the relative room pressurization, which is displayed on the panel.

If there is an anteroom between the isolation room and the corridor, the pressure differential to be measured is the one between the isolation room and the ante room. Or in the best case two differential pressures can be measured and displayed. One between the room itself and the anteroom and another differential pressure reading between the anteroom and the corridor.

The location of the differential pressure sensor can affect the accuracy of the measurement. They should be installed as close as possible to the isolation room door, but away from drafts. A wire from the panel will run to the actual pressure sensor itself and clear plastic tubing will need to be run from the sensor to the static pressure port in each area. This tubing will typically be run out of sight inside wall cavities and above the ceiling.

Alarm(s) and Controls

In addition to providing a continuous readout of the pressure difference, the wall panel should include an audible and visual alarm to warn staff when pressurization is lost. The alarm will sound when the measured room pressurization drifts to less than the monitor’s reference pressure value. The reference pressure value is programmed by the user. It will be a value between the steady state pressure differential maintained by the room and zero (neutral pressure). For example, in a room with a steady state pressure differential of minus 0.03″ W.C., the alarm could be programmed to activate when the pressure differential rises to minus 0.001″ W.C. Minus 0.001″ W.C. is the reference pressure value.

The wall panel should also allow staff to program a time delay between loss of pressurization and alarm activation. The time delay will allow staff to enter and leave the room without setting off the alarm. A typical time delay is 45 seconds but could be as much as several minutes. The audible alarm is usually a beeping sound, which will stop when negative pressure is restored or when silenced with a screen touch.

The visual alarm usually consists of a red warning light. Most wall panels also have a green “normal” or “safe” light, which indicates that the monitor is operating and negative pressure is within programmed parameters. The best wall panel displays now show the differential pressure in a green font if the pressure is within ‘safe’ limits and in a red font if the pressure differential falls or rises too high.

Like the audible alarm the visual display will reset once the pressure returns to expected levels, however the max/min indication will remain red indicating that the pressure was too high or low at some point since the last time it was checked.

Max/Min Pressures

The best differential pressure monitors have a max/min feature which continually shows the high and low pressure reached since it as last reviewed. This ensures that someone is regularly checking, not only the current pressure, but is also aware if an unsafe pressure occurred in the past.

Remote Alarm

In addition to the alarm included on the wall panel, most room pressure monitors include an extra relay to trigger an alarm signal in a remote location, such as the nurses’ station, a central switch board, or the engineering department. The best pressure monitors can be set to send an email or text alert if an alarm occurs. In some states, for example, the hospital building codes require that negative pressure isolation rooms be equipped with an alarm that annunciates at the room and at a nurses’ station or other suitable location.

Commissioning and Staff Training

The monitor installer’s responsibilities should include verifying the operation of the sensor. The following should be completed before the room is used to isolate suspected or confirmed infectious TB patients:

- Verify that the alarm works. Hold the room door open. After the time delay, the audible and visual alarm should annunciate. The alarm should reset after the “mute” or “reset” button is pressed and/or the door is closed again.

- Verify that the monitor is correctly reading the pressure. While the door is held open, the pressure reading should be at or near 0″ W.C.

- Instruct staff in monitor usage. The floor staff who depend on the monitor for their safety should feel comfortable using it. They should receive detailed instructions on how the monitor works and how it is.